Treatment of micropollutants

The removal of micropollutants (RMP) is the latest requirement in wastewater treatment. Organic micropollutants are removed from wastewater by oxidation and/or adsorption. The negative ecotoxicological effects of micropollutants on our waters and their living organisms are thus massively reduced. Techfina plays an important role in the development and large-scale implementation of innovative RMP processes and installs state-of-the-art equipment in wastewater treatment plants. All of our RMP processes also separate solids, retain them and remove phosphorus.

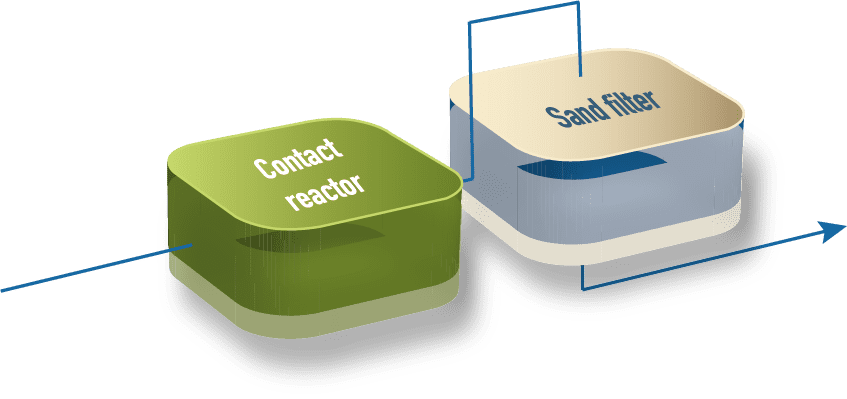

Ozonation and sand filtration

After the biological treatment, the micropollutants are chemically decomposed by the addition of ozone so that they no longer have a harmful effect on the environment. The resulting oxidation by-products are biologically degraded in the subsequent sand filtration. This process is suitable for municipal wastewater.

Granular activated carbon (GAC)

The water to be treated percolates by gravity during a certain contact time through the granular activated carbon filter which adsorbs the micropollutants. The saturated filter material is regenerable and can be reused. This process is suitable for municipal and industrial wastewater.

Powdered activated carbon (PAC)

Powdered activated carbon (PAC) is introduced directly into the wastewater to adsorb micropollutants. The saturated PAC is retained by downstream sand filtration. This process is suitable for municipal and industrial wastewater.

Granular activated carbon (GAC) in the DynaSand® Carbon filter

The wastewater flows through the Dyna-CAG filter from bottom to top, which ensures that micropollutants are reliably adsorbed. An air lift pump transports the filter material to a washing system. This process is suitable for municipal and industrial wastewater.

Micro-grained activated carbon (µGAC) in a fluidized bed

It is a particularly compact, easy-to-operate and inexpensive process for the removal of micropollutants. The wastewater flows from the bottom to the top of the reactor through a layer of fluidized activated carbon located in the lower part of the reactor. The higher specific gravity of the carbon creates a separation layer between the activated carbon bed and the clean water, which can be discharged through an overflow. This process is suitable for municipal and industrial wastewater.