Biological treatment

The biological treatment step (BIO) is the centrepiece of every wastewater treatment plant. Microorganisms aerobically and anaerobically degrade and remove the carbon and nitrogen compounds contained in the wastewater. This reduces the amount of available nutrients in waterbodies and prevents excessive algae growth, putrefaction and hygienic deterioration.

Techfina SA has successfully furnished the biological treatment step of more than 100 wastewater treatment plants. The process engineering technology and components supplied by Techfina SA are characterised by high energy efficiency, operating reliability and durability.

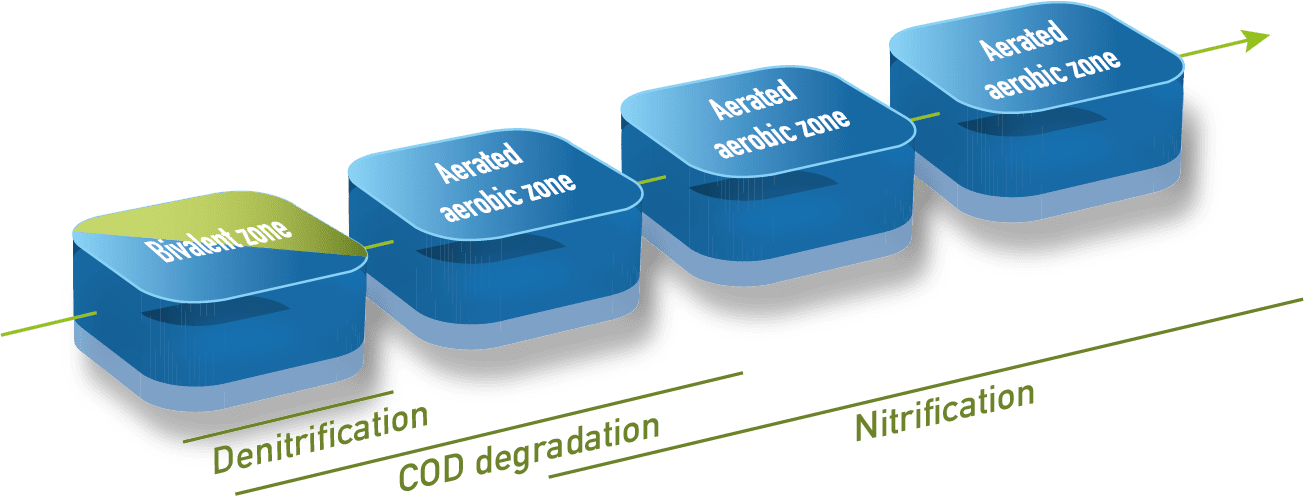

Conventional Process

Classical reliable and time-tested activated sludge process for COD removal, nitrification and denitrification. The biomass responsible for the process is made up of bacteria in suspension (activated sludge). Optimal conditions are created for the various heterotrophic and autotrophic bacterial species involved in the different biological processes.

A/I Process

Activated sludge process with alternating and intermittent nitrification and denitrification. The reactors are aerated only for as long as necessary according to the current loads, which significantly reduces the electric power consumption of the process.

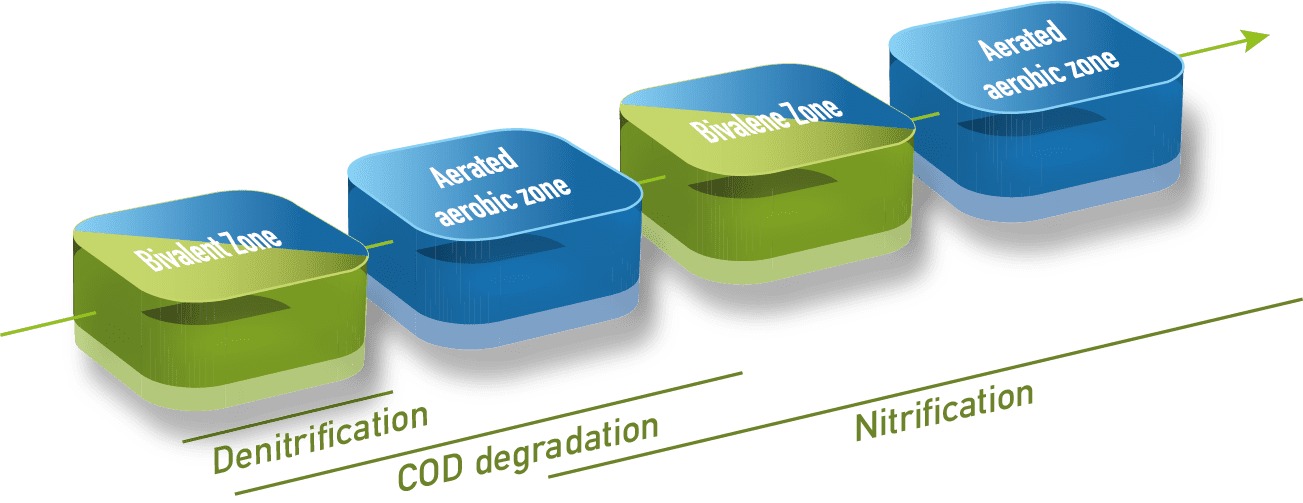

Dynamic Nitrification

Improved activated sludge process for new and existing plants. Our enhancement of the classical activated sludge process allows for operation adapted to the current loads, which reduces the electric power consumption of the process and increases the nitrogen elimination rate.

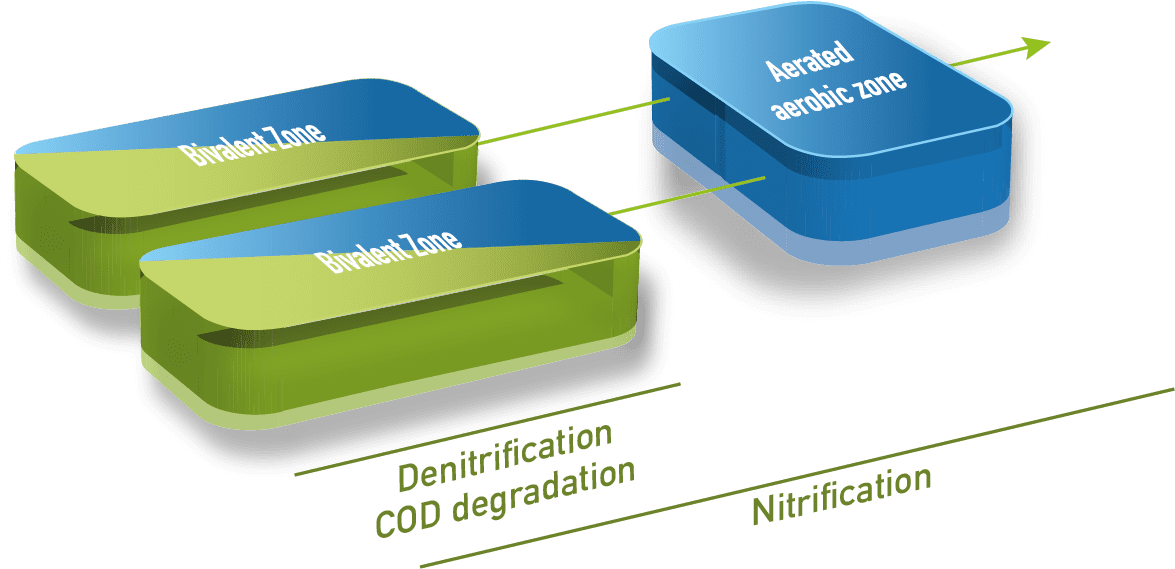

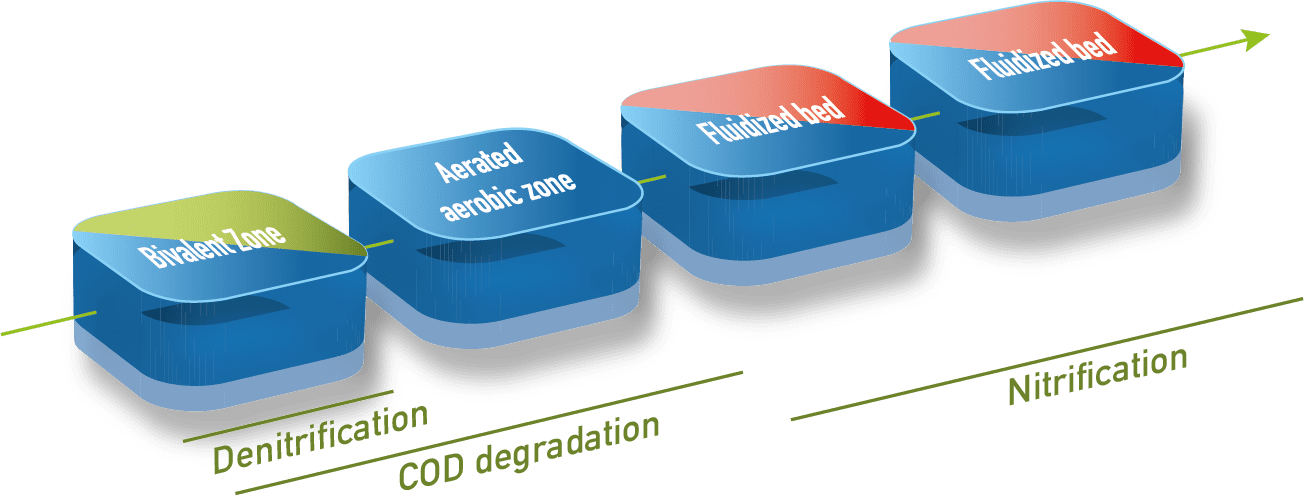

Hybrid Fluidized Bed / Hybrid Moving Bed

Space-saving, low-investment process for existing plants. This process increases the capacity of conventional activated-sludge plants by addition and retention of a fluidized biofilm carrier. The process is carried out by suspended biomass as well as by biomass growing on the carrier (biofilm).

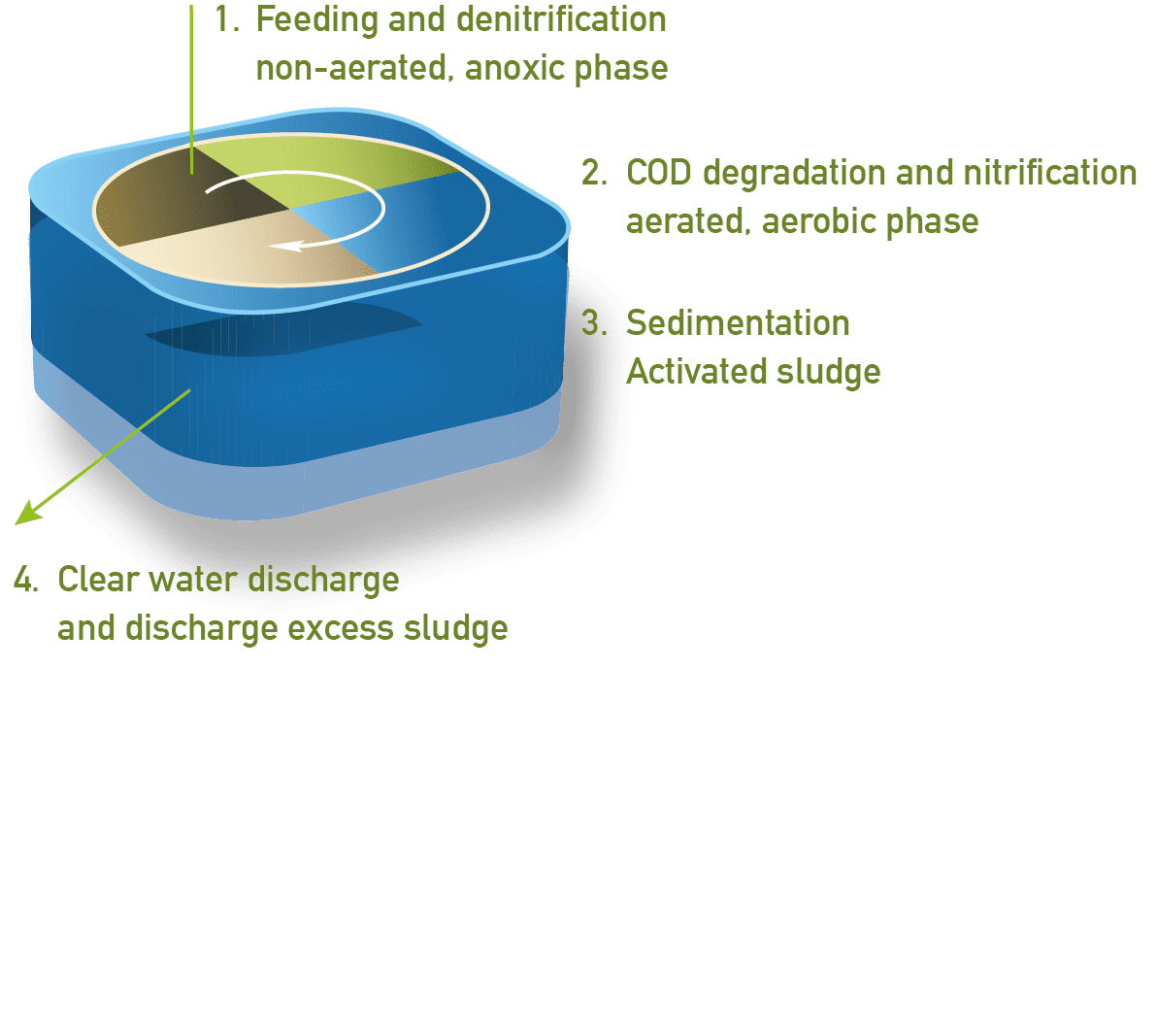

SBR Process (sequencing batch reactor)

Space-saving, highly-flexible process. The individual process steps are carried out in sequence in the same batch reactor. The process can be adapted to your requirements, i.e. to the diurnal and seasonal variations in the hydraulic, COD and nitrogen loads.

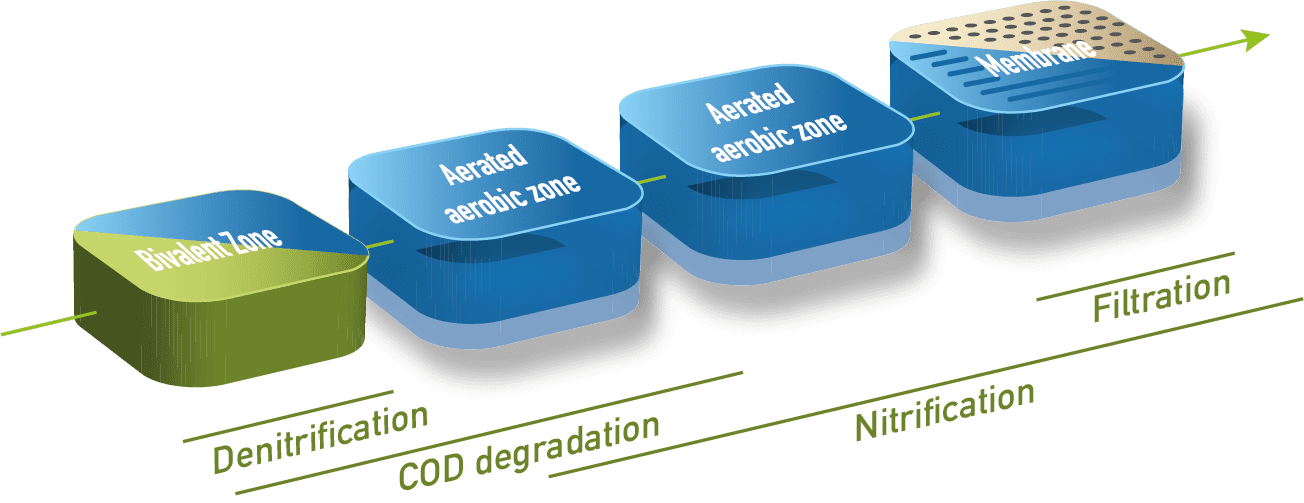

MBR process (membrane bioreactor)

Space-saving, compact process that allows for operation of the biological reactors at high suspended-solids (biomass) concentrations. Compact membrane modules are placed directly into aeration tanks and retain suspended solids and bacteria. This process combines both secondary clarification and filtration and integrates these steps into the biolgical step.